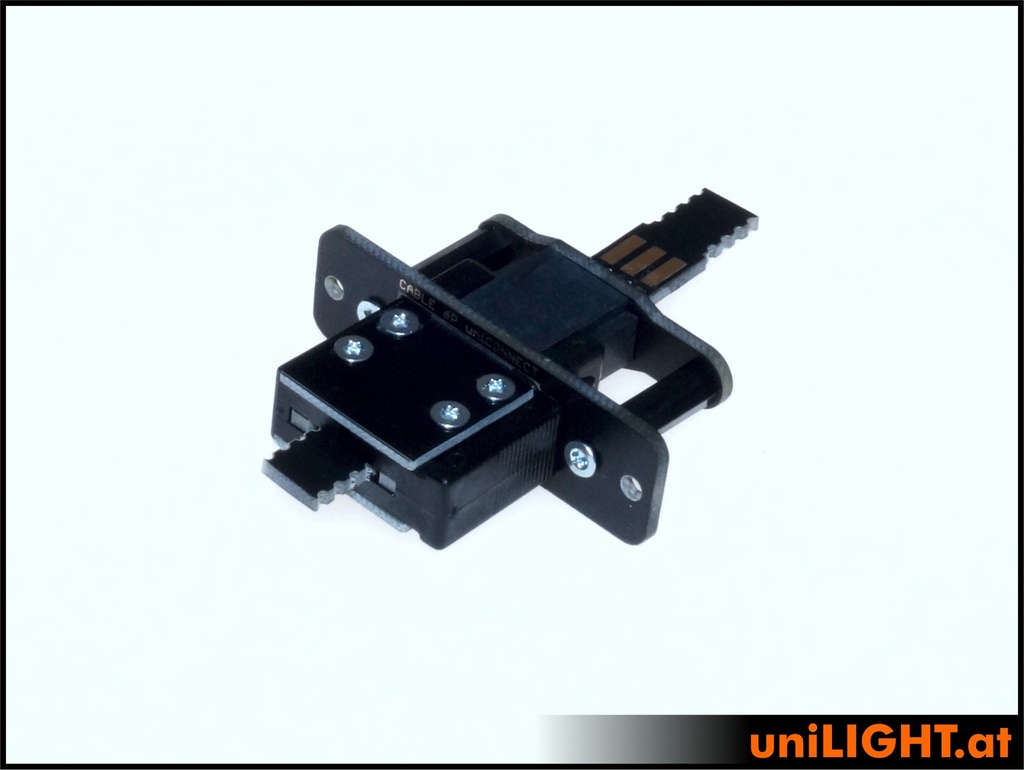

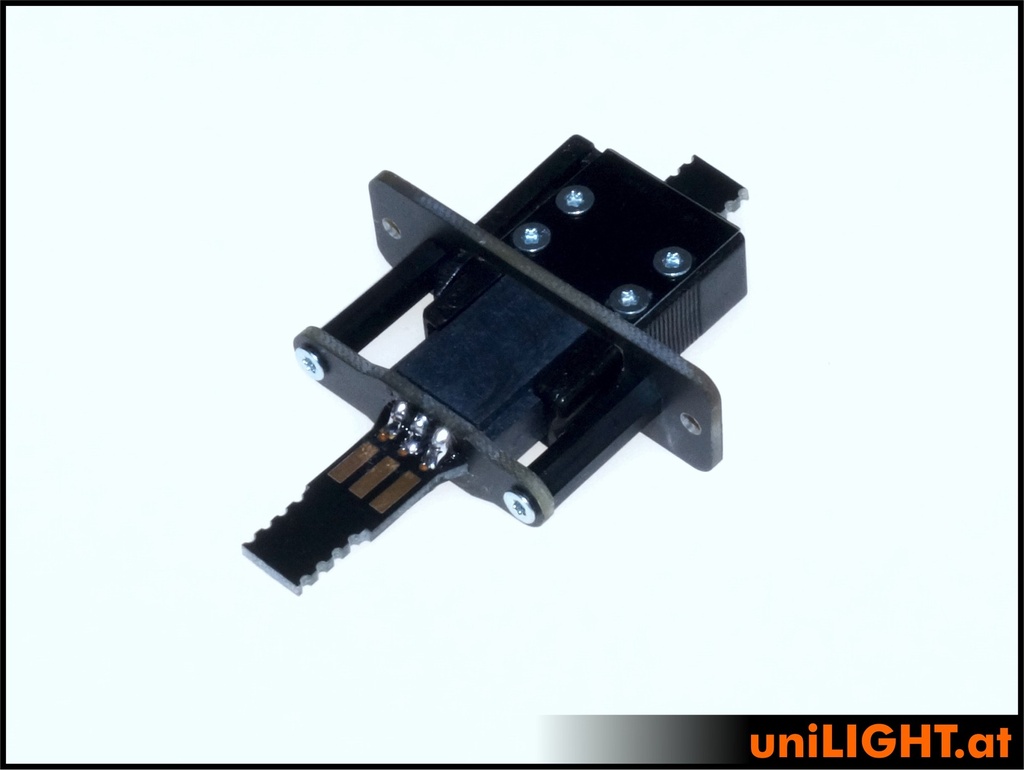

CABLE connector, 6S contacts

CABLE-6S

The uniCONNECT connector system uses solid blade contacts and highly durable base strips. With this new design, high pin counts in a compact connector can now finally be realized – up to 28 pins. It allows for more than 3000 cycles with load capacities of up to 10A, making it optimal for use in model making.

The blade strips have the advantage that all cables can be reliably and easily soldered without the risk of melting a plastic carrier. Additionally, they include strain relief, locking mechanisms, grips, and kink protection. The contacts on the blade strips are always visible, making it easy to detect any damage or contamination immediately.

The greatest advantage of the system is that it provides double redundancy for important control functions within the connector itself. Therefore, the system distinguishes between primary pins (doubled, for main functions) and secondary pins (single, for lights, landing gear, brakes, etc.), unlike traditional systems that only specify pin counts.

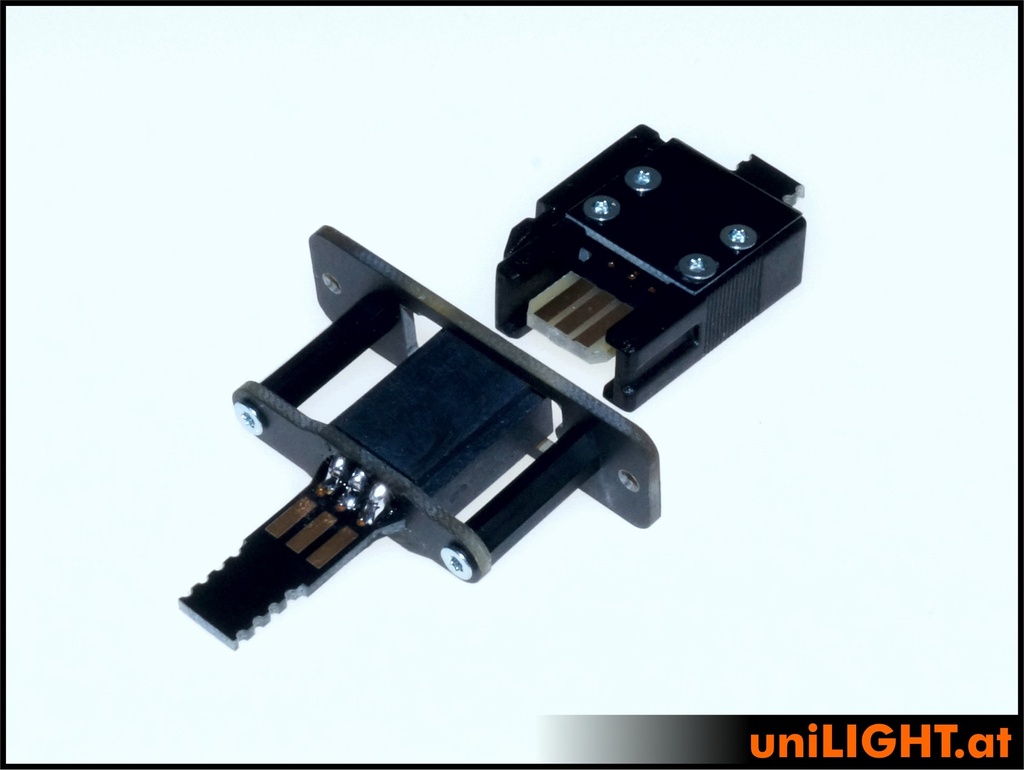

Locking CABLE is a classic connection type where a socket is permanently installed in the fuselage, and the cables from the wing are connected to a plug. This plug is inserted into the socket during assembly and locks in place. The remaining cable is then pushed back into the wing after the plug is connected.

6 secondary contacts for additional functions, 5A

3000 cycles,

strain relief, handle and bend protection

Easily accessible contacts and soldering points

Classic connector with secure locking

Pre-assembled with 3m cable (0.35mm²)

Available as a kit with all parts and screws

cover dimensions: 13x42mm

Connector weight: 10g without cable

RTR

Fully assembled and soldered unit with 3m cable, directly connected 1:1. It is installed on one side, the length defined to the servo, and assembled with crimp contacts. The remaining cable is routed to the receiver side and then assembled. This completed unit is always delivered as a single piece, i.e., 1xM and 1xF

DIY

Kit for modelers with all individual parts and screws for custom-assembly. This option is naturally very cost-effective, and two pairs are always included, i.e., 2xM and 2xF as a kit.

RTW

Pre-assembled connector, where only the cables need to be soldered. The plate assembly has already been done. Delivered as 2xM and 2xF.

Ready-to-Run / RTR:

Fully wired connector with 3m straight-through cable for a primary servo connection (main functions like ailerons, flaps, etc.). 1 pair (1xM / 1xF).

Ready-to-Wire / RTWR:

Pre-assembled connector with free soldering points for custom realization of a servo connection (main functions like ailerons, flaps, etc.). 2 pairs (2xM / 2xF).

DIY Kit:

Kit for a connector with 3 redundant contacts for a primary servo connection (main functions like ailerons, flaps, etc.). For experienced modelers, includes all parts and screws for assembly, 2 pairs (2xM / 2xF).

Documents

Socket:

When installing the socket, make sure that the areas for the locking mechanism are free so that it can properly snap into place. Only use the provided shrink tubing with inner adhesive for securing the cable.

Plug:

When attaching the side plates, ensure that the small screws hold the male connector in place. If this is not immediately possible, the holes in the side plates can be slightly adjusted. The locking clips can be softened with some heating and bent back into shape if they have lost tension.

Always use primary contacts for main functions!

?unique=c316306)

?unique=c316306)